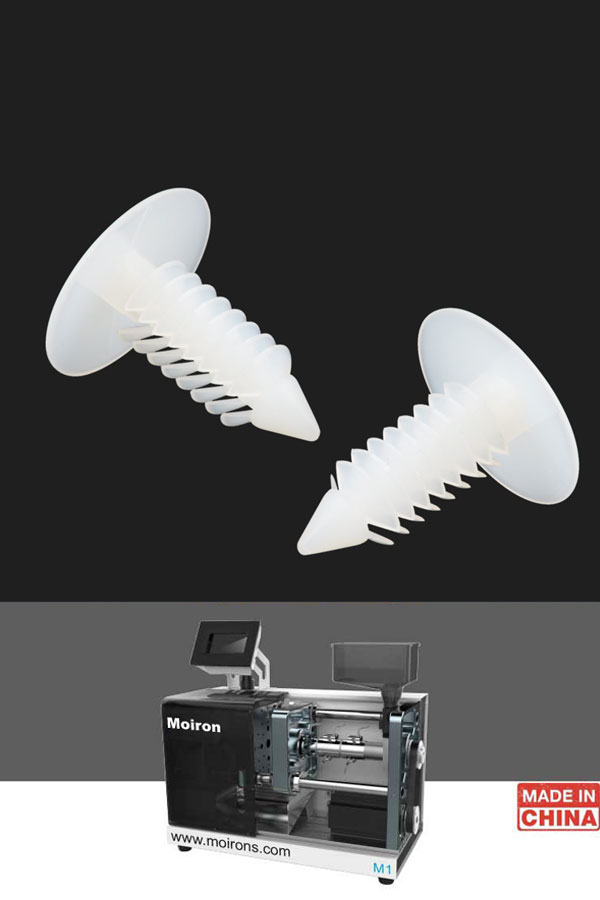

Moiron Micro injection Molding Machine

- Temperature Control Range: 5-300 degree

Heating Connect Point: 3 points

Injection Speed: 220 rpm

Control System: Touch screen

Shot Weight: 25 grams

Machine Weight: 45kgs

Suit Plastic: PP,PS,PP,PE,ABS

- Hotline:0086-13757444218

-

Product details

Moiron Micro injection Molding Machine feature as below:

- Compact design

- Strong body structure with stainless steel, aluminum 6061, bronze parts

- All electric and no water-coolant system

- Full automatic with precision sensors

- Injection speed control for fill rate

- Electronic temperature control system

- User touch screen for operational control

- Injection capability with 3D printed molds

- Typically 60 secs per injection cycle (clamp opens and ejects parts every 60 secs)

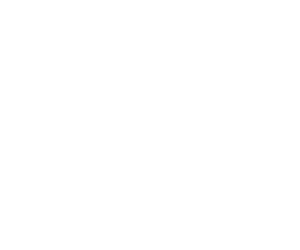

Three advantages of injection molding

1 - Low scrap rates

Relative to traditional manufacturing processes like CNC machining which cut away substantial percentages of an original plastic block or sheet, scrap rates are so low. Note: waste plastic from injection molding manufacturing typically comes consistently from four areas: the sprue, the runners, the gate locations, and any overflow material called “flashing”.

2 – Repeat-ability and Accuracy

The second part you produce is going to be practically identical to the first one. This is a wonderful characteristic when trying to produce brand consistency and part reliability in production. Plastic injection molding is such a precise method that the finished product to be very precise. In fact, accuracy is typically within 0.005 inches.

3 – Wide range of material selection

Most polymers may be used for injection molding, including all thermoplastics, some thermosets, and some elastomers. One cool benefit of plastic injection molding is that fillers can be added to components during processing, reducing the density of the liquid plastic while adding enhanced strength to the finished part. Plastic injection molding is an ideal process for industries or products where parts need to be strong. This allows product designers to choose from a vast selection of materials so they can choose exactly the right properties for the injection molded parts they need.

|

Material |

Thickness (in) |

Mold Type |

|

PE |

0.030-0.200 |

Standard |

|

PP |

0.025-0.150 |

Standard |

|

TPE |

0.020-0.250 |

Standard |

|

PS |

0.035-0.150 |

Standard |

|

Acetal |

0.030-0.120 |

High Temp |

|

ABS |

0.045-0.140 |

High Temp |

|

PC |

0.04-0.150 |

High Temp |

Order:Moiron Micro injection Molding Machine