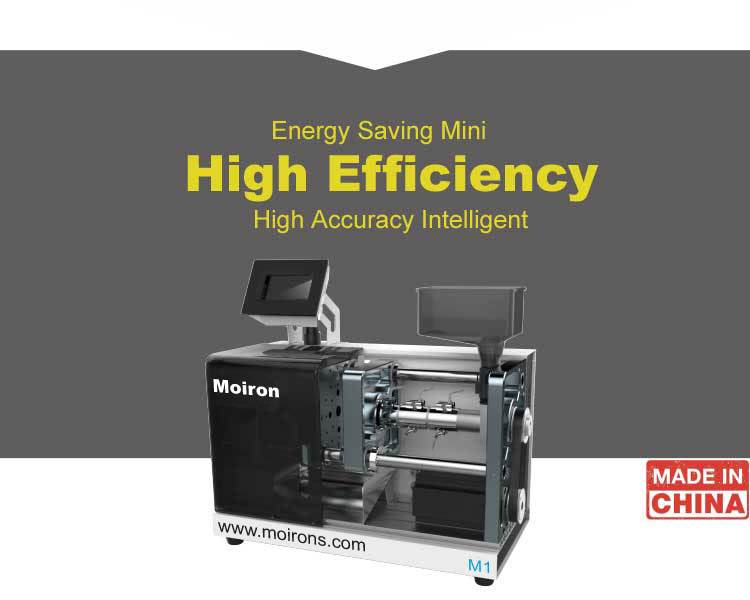

M1 Desktop Injection Molding Machine for sale

- Machine Size: 600mm*300mm*530mm

Machine Weight: 45kgs

Screw Diameter: 16

Injection Unit Motor Torque: 12N*m

Clamping Unit Motor: 8N*m

Maximum shot Weight: 10grams

Maximum Clamping Force: 20KN

Temperature Control Range: 50C-350C

Heating Connect Point: 4 heating band

Mold Opening Stroke: 135mm (not included mold)

Maximum Mold Size: 150mm*150mm

Injection Speed: 12second (5grams PP material )

Control System: 5 Inch touch screen

Power: Single Phase 220V/1kw

- Hotline:0086-13757444218

-

Product details

Moiron M1 Desktop Injection Molding Machine for sale

Machine Feature:

Automatic desktop injection molding machine with a small size:600mm*300mm*530mm

All electric .

Full automatic control of molding actions, pressure, time and temperatures.

1″ steel bar construction.

Precision ballscrews and sensors.

Touch screen tablet PC for user control

Precision distance, temperature and pressure sensors

Repeatable processes once injection profile file established

No water cooling line installation required

Machine Warranty:

1 year part replacement warranty

Maybe you need desktop injection molding machine

Low Volume Manufacturing-If the part will not be consumed more than 300K pieces a year,Moiron is best choice.

Engineering Prototype, Research and Development-

It also allows a clear separation of the cost accounting of the daily conventional manufacturing processes from the costs of product development.

Hobbyist / Engineer Alone-

You may start a new business while keeping your day job. One of the problems of this is the difficulty in establishing relationships with local businesses when you have limited working hours.

it's ability to work with a wide variety of plastic resins. This includes:

Acrylonitrile Butadiene Styrene (ABS)

Acetal

High Density Polyethylene (HDPE)

Polypropylene Plastic (PP)

Polystyrene (PS)

Thermoplastic Elastomeric Olefin (TPO)

What kinds of plastic products can be made by this desktop injection molding machine.

Cap snap buttons

|

Plastic Caps

|

The unit includes a 5" touch screen to control all functions of the process. From here you'll be able to start and stop the machine, make adjustments to settings, and monitor the progress of each cycle.

It requires 220V power and utilizes a heater of 1200W. It utilizes air cooling for the mold area so no dedicated water supply is necessary. An electronically controlled fan is built into the top of the molding area. The temperature is precisely controlled throughout each cycle using a setting in the control panel. Once this is set the unit monitors the temperature and adjusts the fan speed accordingly

Order:M1 Desktop Injection Molding Machine for sale