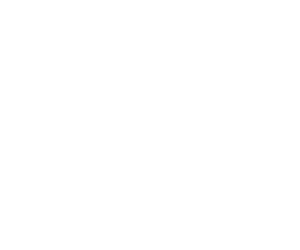

M2 Mini Injection Molding Machine

- Machine Size: 600mm*300mm*530mm

Machine Weight: 48

Screw Diameter: 16

Injection Unit Motor Torque: 12N*m

Clamping Unit Motor: 8N*m

Maximum shot Weight: 30 grams

Maximum Clamping Force: 100KN

Temperature Control Range: 50C-350C

Heating Connect Point: 4 heating band

Mold Opening Stroke: 135mm (not included mold)

Maximum Mold Size: 150mm*150mm

Injection Speed: 12second (5grams PP material )

Control System: 5 Inch touch screen

Power: Single Phase 220V/1kw

- Hotline:0086-13757444218

-

Product details

Mini Injection molding machine

High accuracy(can make small parts weight<0.01g micro product)(Leading technology)

1):PID temperature control±1℃

2): Mold clamping accuracy 0.01mm

3): Shot weight accuracy 0.01g

4): Shot peak pressure 1kg

The machine is especially designed for small parts; precise screw injection system make sure the high accuracy of minimum shot(even if shot weight<0.01g); adopt servo control system, 24 high accuracy absolute encoders with good stability and high accuracy Repeatability , improving the stability of product shaping

1.Mini Size:

Our mini injection molding machine covers an area of about 1square meters,and can build mini injection workshop, saving investment of workshop and mold.

Machine dimension:600mm*340mm*530mm;

Net weight:45kg.

2.Energy saving(0.75KW/h)

Traditional hydraulic press 15KW/H

Moiron Mini automatic press 1KW/H

Servo energy saving injection press is equipped with high performance servo electric motor driving control system. Output power of servo motor varies as loading changes so more energy consuming is not existing. During keeping pressure state, motor rotating decrease with low energy consuming. During cooling state, motor is nearly not working. The shot accuracy is improved, at the same time electricity, water saved.

3.High performance

Quality control(Cycle/remaining/injection time)

Automatic shutdown when alarming

PID temperature control

Electrically heated mold(without no mold heating machine)

Ready state temperature

Machine operation speed controllable

Mold voltage protection function

Screw torque protection

Four clamping speed

Four injection

Four keeping pressure

Four metering

Automatic mold adjustment program

Communication instructions for servo and upper machine (good anti-interference)

Automatic refueling for active parts

Middle mandrel speed up to 99

Mandrel speed and torque controllable

4.High efficiency: 3.5s shaping cycle

Traditional hydraulic press:

Shot speed: 160~200mm/s

Molding cycle :7~10 /s

Mini:

Max shot speed: 500mm/s

Molding cycle 3.5 /s

Simple and individual interface

Different language display

Deal and save 100 sets mold information

Product counting- Production batch setting

Exit program

Counter

Let featured

Purging program

Injection and clamping position precision measurement

Pressure Servo and precision load measurement sensor closed-loop control

The absolute 24 value of the servo motor

Four barrel temperature control zone(Hot runner heater)

Two Thermostat for Mold (two heaters)

5.Intelligent

Few people at site or realize unmanned.

Computer/cellphone: business trip for you to connect internet to know the situation of the machine.

You can operate and monitor the machine on your office.

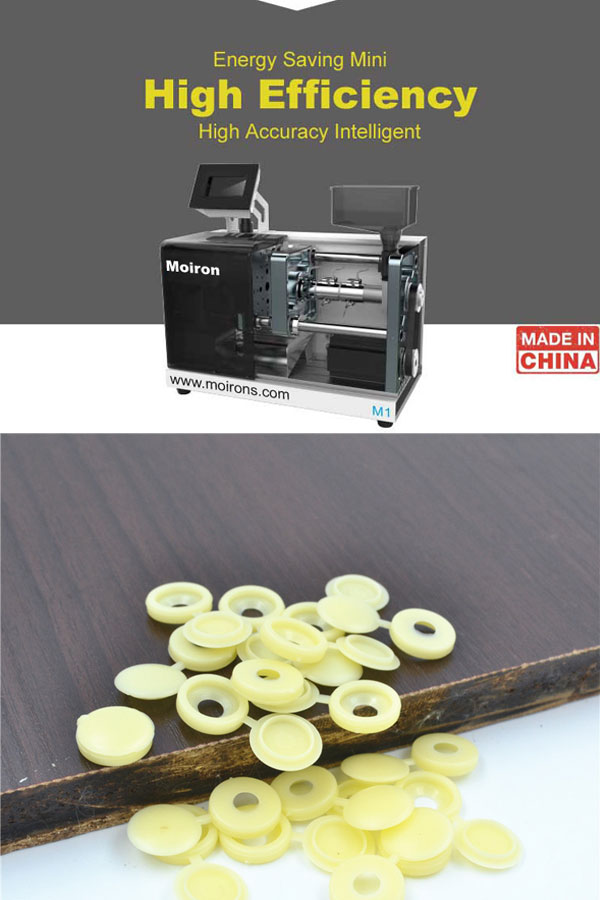

6.Application

Micro-precision parts production

Long-term or small orders

Laboratory testing /making samples

Test-production

Clean room production

Teaching and training

7.Quality

Ultra-high-speed performance dual-core CPU,Computing speed 0.13us,Scan time 1ms

Servo control system uses MECHATROL+INK embedded CNC technology,Substantially increasing plasticized performance,switching speed of change.

Servo motor is equipped with absolute encoder 24;if power failure or power outage to replace the mechanical parts,it also real-time memory location.

Employ servo feedback mathematical precision torque control + high precision load sensors, to realize high precision measurement of plastics.

Moiron is an automatic injection molding machine with a small 600mm*300mm*535mm. It is a good fit for low-volume (less than 100K/yr) production, prototyping activities, technical colleges, and hobbyists:

· No water cooling line installation is required

· Plugs into your standard wall outlet (110V)

· One year part replacement warranty

Moiron as an alternative to the expensive overpowered large injection molding machines that are typically over designed for R&D, Prototyping, Product Design, Education, Hobby and other Low-Volume production environments

| Do you have any question? |

|

Order:M2 Mini Injection Molding Machine