How to choose a desktop injection molding machine for prototyping?

Many customers ask me how this product is made, it's actually not that complicated, it’s mostly just heat, pressure, and a bit of patience. I was sitting in my shop the other day, looking at a pile of failed prototypes, and it got me thinking about how hard it is to actually pick the right gear when you're just starting out.

I remember when I first decided I needed to move away from 3D printing. Don't get me wrong, I love my printer. It’s great for checking if something fits together. But have you ever tried to use a 3D printed gear in a machine that actually does real work? It snaps. It always snaps. I got so tired of parts breaking that I decided I needed to get into injection molding. But I didn't have room for a factory floor, you know? I just had a corner of my garage and a workbench that was already too cluttered. So, choosing a desktop injection molding machine. It’s a bit of a nightmare if I’m being honest. There are so many options now compared to ten years ago. Back then, you basically had to build it yourself or buy something that looked like a toaster oven welded to a drill press.

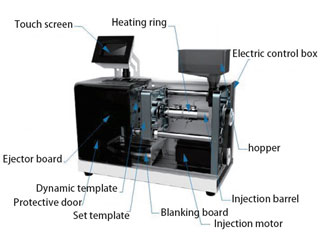

The first thing I tell people—and I learned this the hard way—is to look at the "shot size." It’s a fancy way of saying "how much plastic can this thing spit out at once." I bought my first machine thinking I was only going to make tiny little clips. And it was fine for that. But then I wanted to make a handle for a tool I was working on. I did all the math, or at least I thought I did, and the handle needed about 30 grams of plastic. My machine maxed out at 20. It was useless. I had to scrap the whole idea or buy a new machine. So, my advice? Whatever size you think you need, get the next size up. It gives you wiggle room. You don't want to be right at the limit, because then you start getting air bubbles and half-filled molds. Another thing is the physical effort. People forget this part. A lot of the cheaper desktop machines are manual. You have to pull a big lever to inject the plastic. It feels satisfying the first five times. You feel like a blacksmith or something. But if you have to make 50 parts? Your arm is going to fall off. I’m not kidding. I spent a whole weekend running a batch of 200 parts on a manual lever machine and I couldn't lift my coffee cup on Monday. If you have the budget, looking for something with a pneumatic assist—where air pressure does the pushing—is a life saver. It’s not about being lazy, it’s about being able to use your arm the next day.

I also feel like people overlook the clamping force. That’s just how hard the machine squeezes the mold shut. If the machine pushes the plastic in harder than it holds the mold closed, plastic squirts out the sides. We call it "flash," but really it’s just sharp, annoying garbage you have to trim off later with a knife. I hate trimming flash. It’s the worst job. I’ve cut my fingers so many times doing that. So, make sure the clamp is strong. A flimsy vice isn't going to cut it if you're pushing thick plastic. And the smell. Nobody talks about the smell. Different machines handle heat differently. If you get a machine with a bad temperature controller, it might overshoot. You set it to 200 degrees, it goes to 240, and suddenly your nice white plastic turns brown and smells like burning tires. My wife banned me from using certain plastics in the house because the smell seeped into the curtains. A good machine holds the temp steady. It doesn't fluctuate wildy.

Honestly, messing up is part of it. I’ve ruined molds, I’ve clogged nozzles (that is a nightmare to clean, by the way), and I’ve burned myself more times than I care to admit. But there is a real magic to it. You put in these little cold pellets, wait a bit, pull a lever, and out comes a solid, real thing. It feels like a real product, not just a fragile print.

It’s a messy hobby, though. You’ll find plastic pellets everywhere. I found one in my shoe this morning and I haven't run the machine in three days. Does that ever happen to you?

Ranking of similar articles

- How to get started DIY injecti

- table top injection molding ma

- desktop fully automatic inject

- May I know how soon I can get

- How to choose a desktop inject

- What is the power consumption

- How long the machine warranty

- How long have you engaged in t

- Mini Injection Mold Machine: W